Quality Management

We have passed ISO9001 and ISO14001 certification in 2005. Ever since then, we have strictly execute corporation’s operation under ISO system. We ensure sufficient and effective quality management through continuous inner inspection, management review and audit. We achieve continuous quality improvement by planning, execution and feedback control.

- Thoughts Guarantee

- Organization Guarantee

- Technology Guarantee

-

With the implementation of strict quality management, all employees are made realize the importance of product quality, and convert that to quality in work and products, thus pay attention to customer demand and improve customers satisfaction. -

With the establishment of robust quality management structure, job responsibilities are defined. Consummate quality management process are carried out to improve employee’s skills and product quality. Duties to perfect quality management and control low are assigned clearly as well.

With the establishment of robust quality management structure, job responsibilities are defined. Consummate quality management process are carried out to improve employee’s skills and product quality. Duties to perfect quality management and control low are assigned clearly as well. -

With full quality inspection of apparatus, such as stiffness tester, whiteness tester, rubbing tester and open strength tester, it provides solid foundation and support for quality control. Together with customers’ requirements, we continuously improve our process control skills to ensure quality.

With full quality inspection of apparatus, such as stiffness tester, whiteness tester, rubbing tester and open strength tester, it provides solid foundation and support for quality control. Together with customers’ requirements, we continuously improve our process control skills to ensure quality.

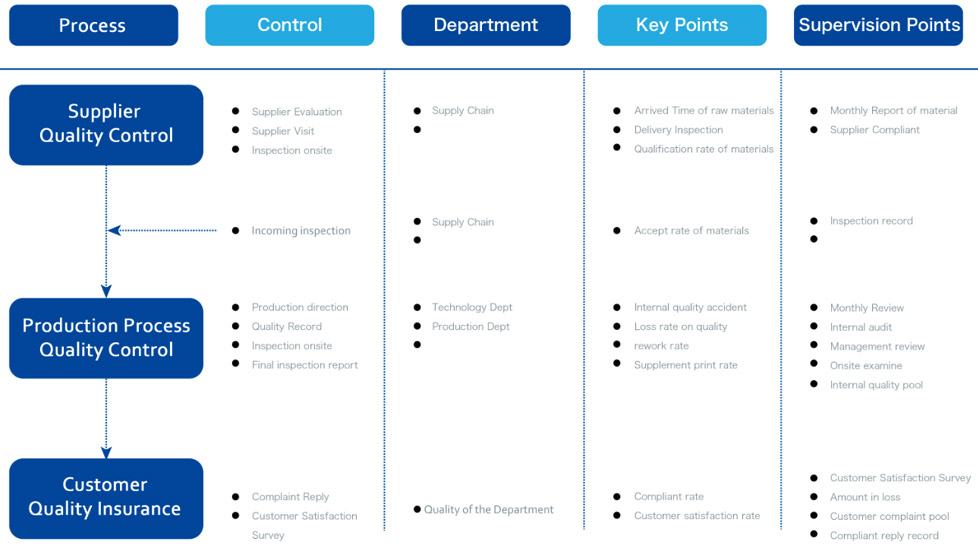

Quality Control

We carry out quality management through the whole process: pre-control, in- process and post control.

- Pre-control

- In-Process Control

- Post Control

-

> In the design stage, quality, technology and production departments will analyze the product from design to ensure reliability, feasibility and achievability

> In the design stage, quality, technology and production departments will analyze the product from design to ensure reliability, feasibility and achievability

> Identify special processes and quality control points which need. based on different customer requirements and product features.

> Emphasize on the inspection and applicability of raw materials to ensure quality.

> Enforce the first inspection for product to ensure every employee know & follow quality requirement. -

> Ensure product quality by self-checks, hand-over checks, and routine inspections to ensure quality.

> Ensure product quality by self-checks, hand-over checks, and routine inspections to ensure quality.

> Apply total inspection by advanced inspection equipment.

> Apply Kanban system and PDCA to feedback and analyze product’s quality in time.

-

>Apply sample inspections to guarantee product quality following predefined inspection standard.

> Collect customer feedback on product quality in time, and continue to improve.

SHGA:31011702000329

SHGA:31011702000329